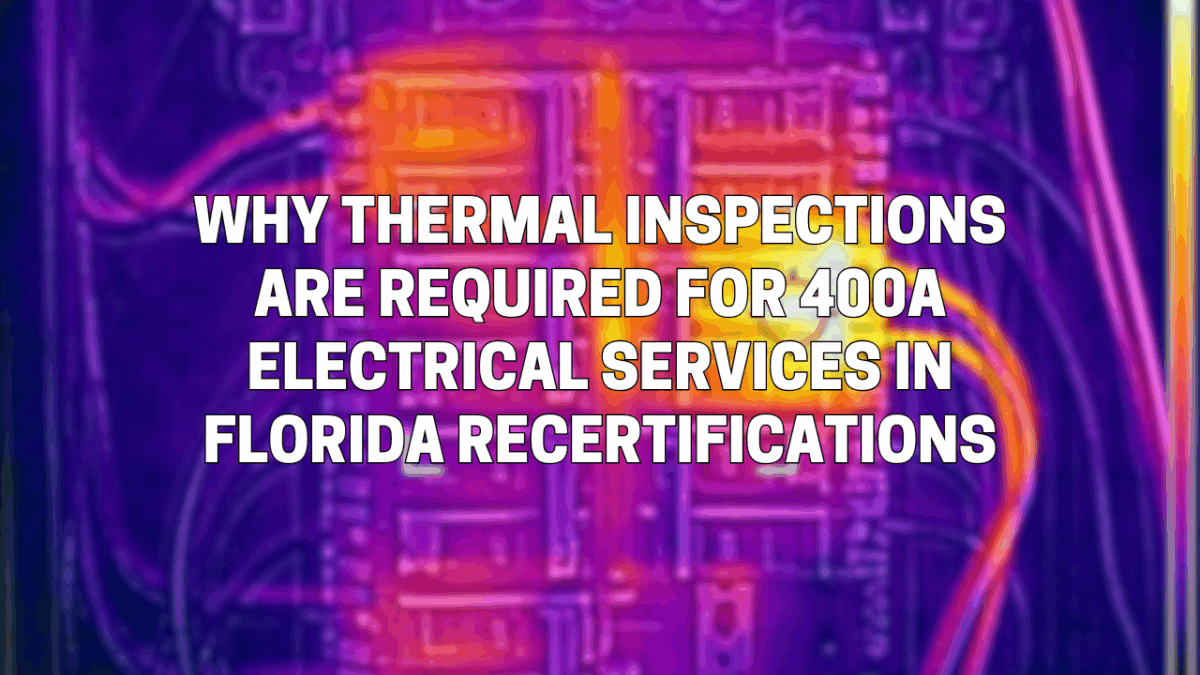

When you’re recertifying a multi-family or commercial building in Florida, the code only mandates infrared thermography once the building’s main service exceeds 400 amperes. Here’s why that threshold exists, and what your IR inspection must cover—illustrated with a real FLIR scan from one of our recent recert projects.

1. The 400 A Threshold: Code & Risk Basis

- Florida Building Code / SB 4-D Recertification

Senate Bill 4-D (2022) and Florida’s recertification regs require a detailed structural and life-safety inspection every 10 years (25 years at or near the coast) for buildings three stories or taller. Section 9.4(f) of our standard agreement (and many jurisdictions’ local amendments) explicitly adds infrared thermography for any building whose electrical service exceeds 400 A. - Why 400 A?

- Higher fault current potential: Larger services carry more current, so any loose lug or overloaded conductor can heat up dramatically.

- Fire hazard: Temperature rises in large feeders or breakers can ignite insulation or bus insulation if left undetected.

- Safety: Owners and inspectors need non-contact methods to verify tight connections before failures occur.

2. What an IR Inspection Must Cover

A compliant infrared scan isn’t just “point and shoot.” Your report needs to document:

- Main Service Disconnect & Metering

- Scan all phases of the service entrance cable terminations and meter lugs.

- Bus Bars & Panel Connections

- Inspect bus‐to‐panelboard connections, including any sub-feed lugs or isolators.

- Branch-Circuit Breakers

- Check every breaker—single and multi-pole—at load and neutral connections.

- Feeder Cables & Splices

- Any mid-run splice or junction box on feeders >400 A must be imaged.

- Switchgear and Motor Control Centers (if present)

- Include door‐mounted breakers, draw-out units, and any load-side connections.

- Load Imbalance & Harmonics

- Identify unusually hot phases that may signal an imbalance or harmonic overheating.

For each item, the report should:

- Record ambient temperature, emissivity settings, and distance to target.

- Provide a clear thermal image with crosshairs on the hot spot and a visible‐light overlay or separate photo.

- List measured temperatures and calculated temperature rise above ambient.

- Offer recommendations (lug tightening, load balancing, further electrical evaluation).

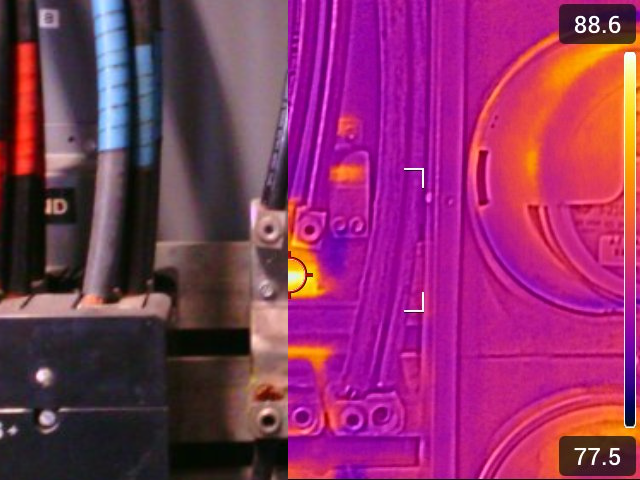

3. Case Study: A 400 A Panelboard Scan

| Figure | Description |

|---|---|

1. Visible Photograph | Shows the building’s main service lugs feeding the meter bank (400 A service). |

2. Split Visible/Thermal | Right half shows the FLIR overlay—only one Right half FLIR overlay highlighting the hottest lug at 89.2 °F (ambient ~77.5 °F). |

3. Full Thermal Scan | Peak of 89.2 °F on the service lug—demonstrates the kind of hot‐spot you must document when >400 A. |

Interpretation:

- Under normal loading you really shouldn’t see those service conductors running much hotter than the surrounding air. Here’s the quick guide:

- Relative (delta-T) guideline

- Ideal: < 10 °F rise over adjacent metal or conductors.

- Acceptable under full load: up to ~15–20 °F rise.

- Anything over ~20 °F should trigger immediate investigation and corrective action.

- Absolute temperature limit

- Conductors are typically THHN/THWN rated for 75 °C (167 °F) or 90 °C (194 °F).

- In practice, you’ll almost never see anywhere near those upper limits on a service entrance—IR scans on a 400 A entrance will usually show absolute temps in the 80–120 °F range (depending on load and ambient).

4. Why You Can’t Skip It

- Non-Invasive & Fast: IR scans take minutes per panel but reveal problems invisible to the eye.

- Code Compliance: Jurisdictions across Florida (e.g., Miami-Dade, Broward, Palm Beach) will reject recertification without the thermography report when >400 A.

- Peace of Mind: Building owners, property managers, and insurance carriers all value the extra layer of electrical safety.

5. Next Steps for Your Recertification

- Schedule your IR thermography with a Florida-licensed engineer or certified infrared specialist.

- Review the full report: tighten any loose lugs, rebalance loads, and repair any hot splices.

- Submit the complete documentation—including thermal images, temperature logs, and repair recommendations—to the local building official along with your other recertification items.

By integrating infrared thermography at the 400 A trigger, you not only satisfy Florida’s recert requirements—you also proactively safeguard your electrical system against hidden heat‐related failures.

Florida Engineering LLC is a Florida-licensed structural and electrical inspection firm. We handle thermography inspections for all recertifications requiring >400 A service.